Liquid stack, a new kinds of battery, requests welded hundreds of layers together in leakproof and clean. Because of state of stack element and material, thus it can not be welded by hot plate. Then we choose linear vibration welding machine in high frequency system to finish welding. Because of high precision control in welding depth step by step, it requests design special welding fixtures to posintion stack parts.

I. Challenging Requirement: 1. Leakage; 2. Clean welding; 3. Very high precision control; 4. hundreds of layers requested to be welded together.

II. Solution: weld by high frequency vibration system in 365HZ, welding depth controlled by servo system.

II. Welding Equipment:

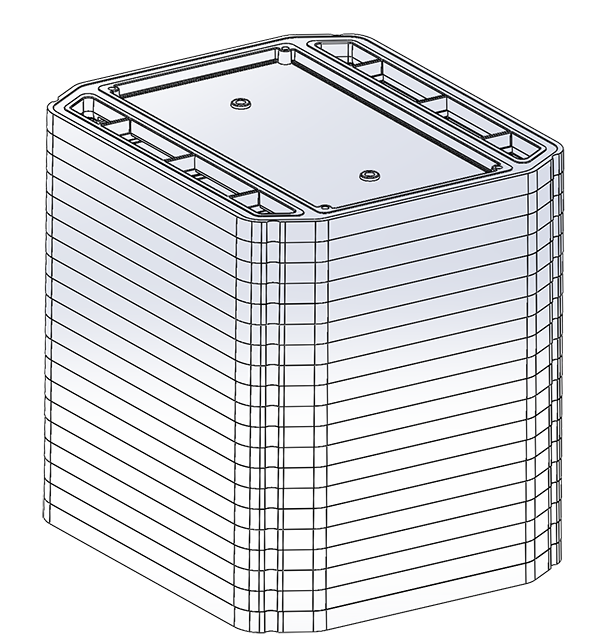

II-1. Servo Vibration Welder MSV/ZB-730LS-S:

FRQ Max.365HZ, Load-Ability Max.70KG, Froced by Servo System.

II-2. Welding Fixture: Vaccum hold in upper fixture, precision servo elevation applied in lower fixture, cylinder clamp positioning in lower fixture, part detection sensor.