Automotive instrument panel (IP), meaning the dashboard of automotive, requests complex assembly in production. The assembly of dashboard requests thermoplastic joining which can be by different welding method, such as vibration welding, ultrasonic welding, infrared welding, etc. Normally it is concerned to dashboard elements including upper dashboard, conditioner dust assembly, screen demist assembly, reinforcement, SAG assembly etc.

I. Parts material: Normally is PP, PP-TD, PE-MD15, etc;

II. Normal Requirement: 1. Welding strength; 2. Protection to surface A; 3. Airtightness for some welding (such as air duct welding).

III. Challenging: 1. Complex geometric shape design; 2. Big measurement; 3. Complex assembly procedure requested.

IV. Welding method might be concerned: A. Ultrasonic Welding; B. Vibration Welding; C. Infrared welding; D. Heat / Infrared stacking, etc.

V. Machine suggestion: A. Vibration for Reinforcement welding, Conditioner Air Channel welding, SGS bracket welding, etc; B. Ultrasonic Spot Welding, or thermoplastic stacking for screen demist assembly welding, etc.

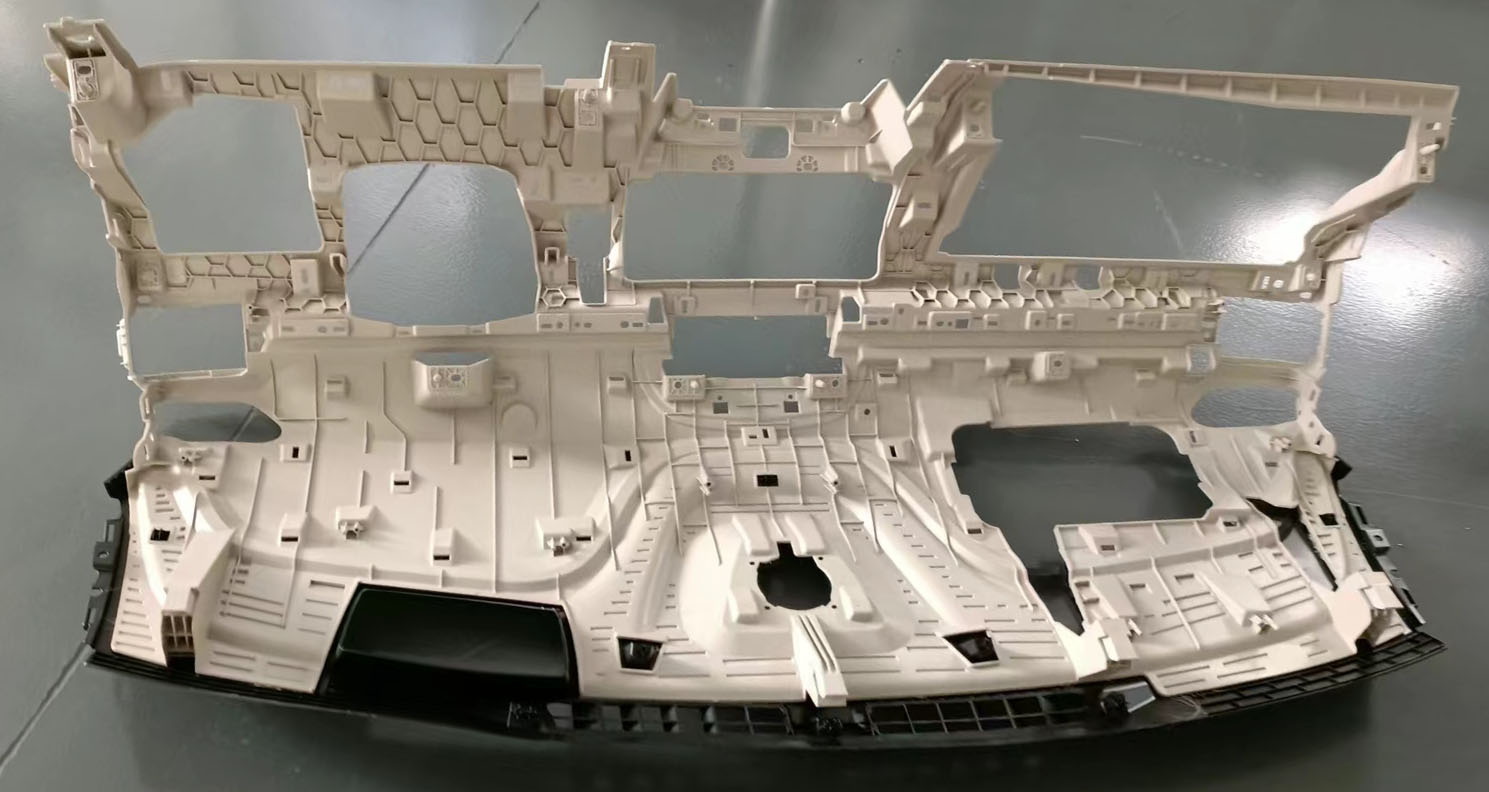

VI. Projects Cases here will show the welding between dashboard upper and reinforcement:

A. Parts material: PP-TD;

B. Welding requirement: 1. In strength; 2. No hurt to surface A; 3. Limit burr volume after welding;

C. Challenging: 1. Big measurement and large welding size; 2. Limit burr volume.

D. Welding Machine Applied: Vibration Welding Machine MSV-830LS (150KG);

E. Vibration Welding Tooling: Made by aluminum by CNC, surface process.

F. Images:

VII. Video