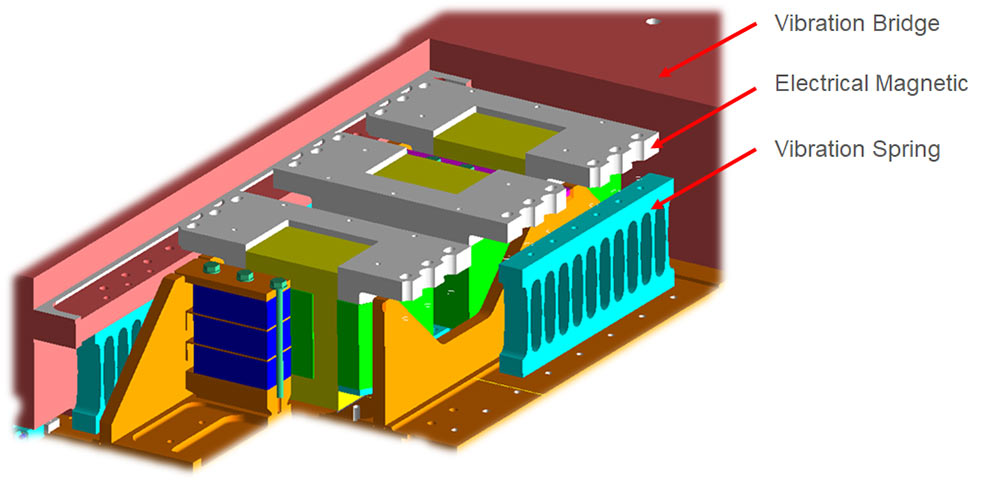

Because of its well-known advantage of high welding ability, linear vibration friction welding is mostly applied for thermoplastic joining with challenging requirement, especially applied to weld parts in big measurement, complex geometric ship design & challenging material. Vibration welding is a type of welding technology apply friction generated by linear vibration in high frequency to melt plastic material at the contacting surface between two plastic parts halves to be welded to achieve jointing result. During welding, the vibration is cased by electrical magnetic together will vibration spring driven by a convertor which is called as amplifier.

Read more about vibration welding technology.

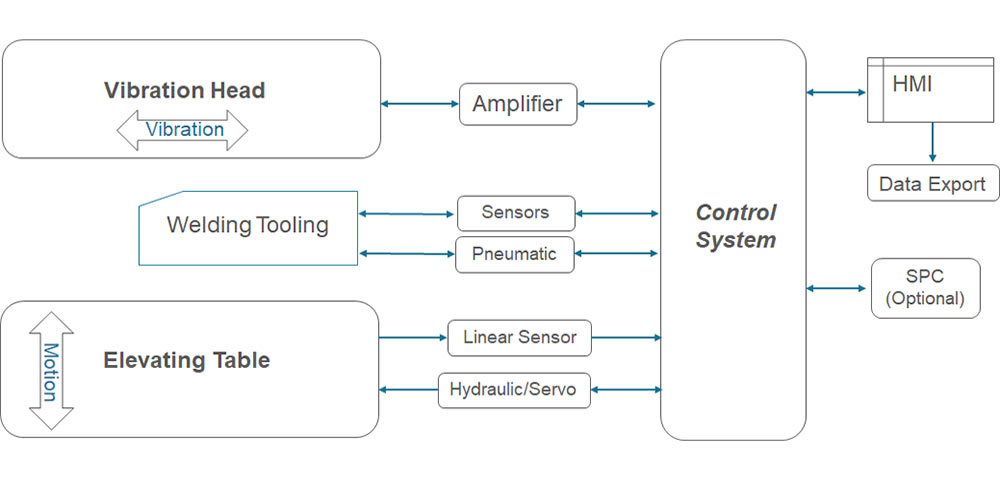

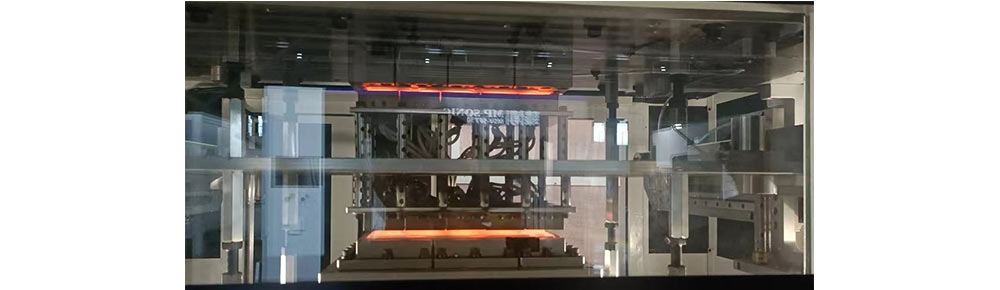

| Vibration Welding Head Structure | Vibration Welding Control Principle |

|

|

|

Advantages of Vibration Welding: 1. High welding possibility 2. High welding capacity; 3. High welding strength; 4. Efficiency in operation; 5. Efficiency in energy utilization; 6. Economical equipment maintenance; 7. Low defective welding rate; 8. Easy correct the vibration existing in parts molded to achievement assembly fitment; 9. Environment friendliness. MP Sonic designs and manufactures vibration welding equipment in specification fit for market requirement with its rich experience & abundant technical force. |

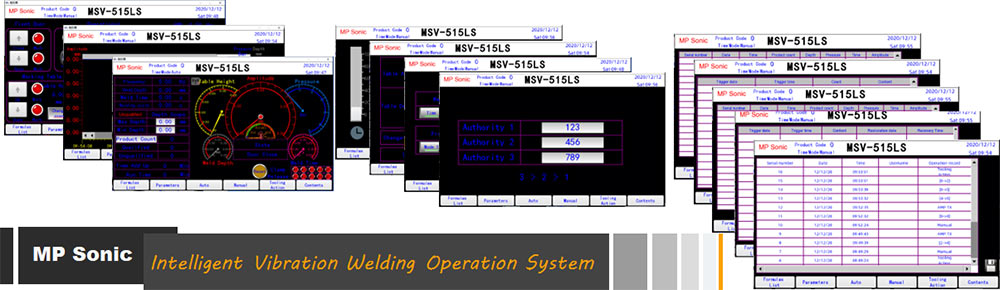

Benefit of MP Sonic Vibration Welding Machine: 1. Higher vibration frequency max to 365Hz affords high welding ability & possibility and perfect welding performance; 2. Reliability in machine construction design and fabrication ensures long duration in precision; 3. Close-loop Servo hydraulic system or pure electrical servo motor welding controlled achieves precision depth & pressure force control, fast action speed, lower power/hydraulic oil consumption, etc; 4. MP Sonic IOP system meets the high requirement in operation and management; 5. Huge features designed afford easy operation in tooling change-over, welding process and ensures high pass-rate in welding result.; 6. Problem free which minimizes machine stopping period and maintenance cost. |

|

|

|

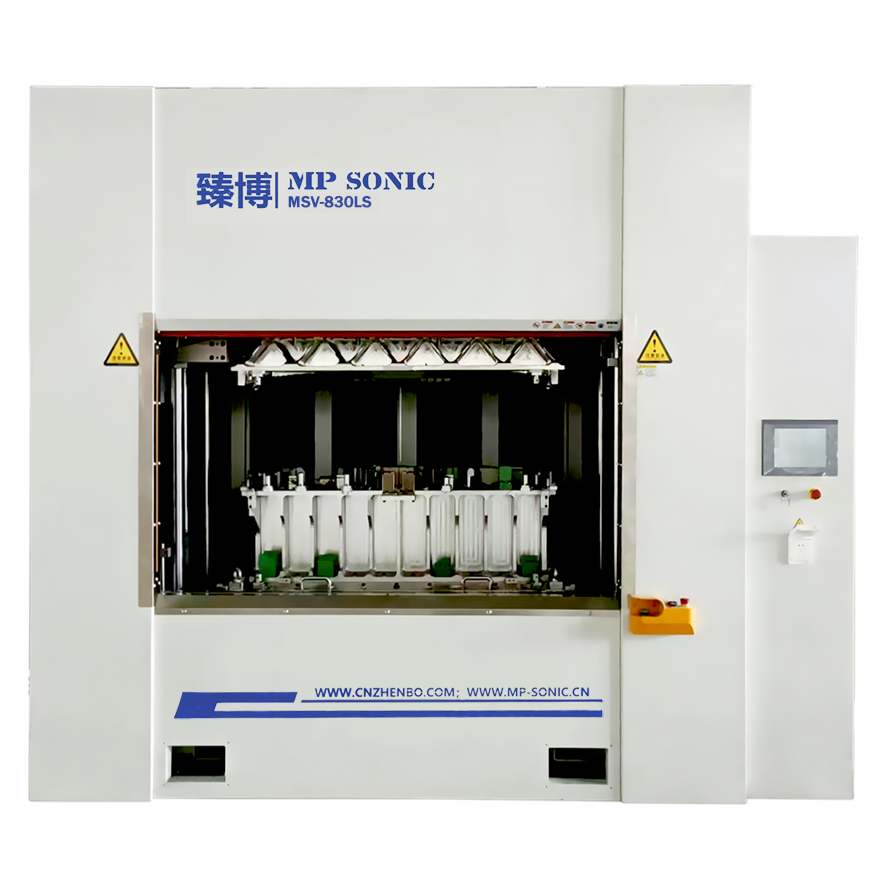

MP Sonic Vibration Welder Series: 1. MSV-LS Series: welding vibration frequency series in 90~170Hz (lower frequency) & 200~280Hz (high frequency); 2. MSV-SF Series: means superhigh frequency, means welding vibration frequency max to 365Hz. |

MP Sonic Welding Force Control: 1. Standard: MP Sonic specially developed servo motor controlled hydraulic system, with the advantages of precision control, high pressure force output, silent operation, lower power consumption and longer hydraulic life time; 2. Pure electrical servo motor control: zero hydraulic consumption, clean in maintenance operation, no pollution to environment and less production consumption cost. |

|

Extra Optional Feature: |

|

1. Hybrid welding (-IR): IR system can be equipped to some machine models to realize pre-heating before vibration welding for some special requirement in welding; |

2. Obit system: Obit system controlled by servo system is equipped with some machine specification for complex parts design or easy loading parts in big size. |