Super-High Frequency Vibration Welder

- Category: Products Center

- Phone: Mr Alex Lee (Commercial Director)

- Fax: +86-577-61517750

- Skype: alexlee2696@hotmail.com

- E-mail: info@mp-sonic.com

MSV-SF series vibration welder applies the super-high frequency linear vibration friction welding technique, which is the newest vibration welding developed by CNZHENBO | MP Sonic, which applies vibration frequency up to 365Hz. The machine by this technology has been certificated as “ The 1st Set of Manufactured Products” by Department of Economy & Information Technology of Zhejiang Province.

With the super have vibration frequency, system achieve enough friction energy to melt plastic material and form thermoplastic welding in vibration amplitude as low as 0.3mm, which with the advantages of clean vibration welding performance, high welding ability and small limit to parts geometric design. (Read more)

I. Benefit

A. High welding possibility: possible to weld on bevel angle max to 45◦ against to vibration direction;

B. Clean vibration welding: no need pre-heating process to material before vibration;

C. High efficiency: shorter vibration time rather than traditional CVT welding;

D. High stability in performance: higher than performance of traditional CVT vibration Welder;

E. Low consumption: lower power consumption than that by traditional CVT vibration Welder;

F. Economical equipment cost: lower investment for equipment and maintenance than that for laser welder and traditional CVT vibration welder.

G. Intelligent management: by MP Sonic Intelligent operation system

II. Features:

1. All features of linear vibration welder MSV-SL series (Read Detail);

2. MP Sonic MSV-SF super-high Frequency Vibration Welding System applied, linear vibration frequency max to 365Hz, realize welding in amplitude minimum 0.3mm:

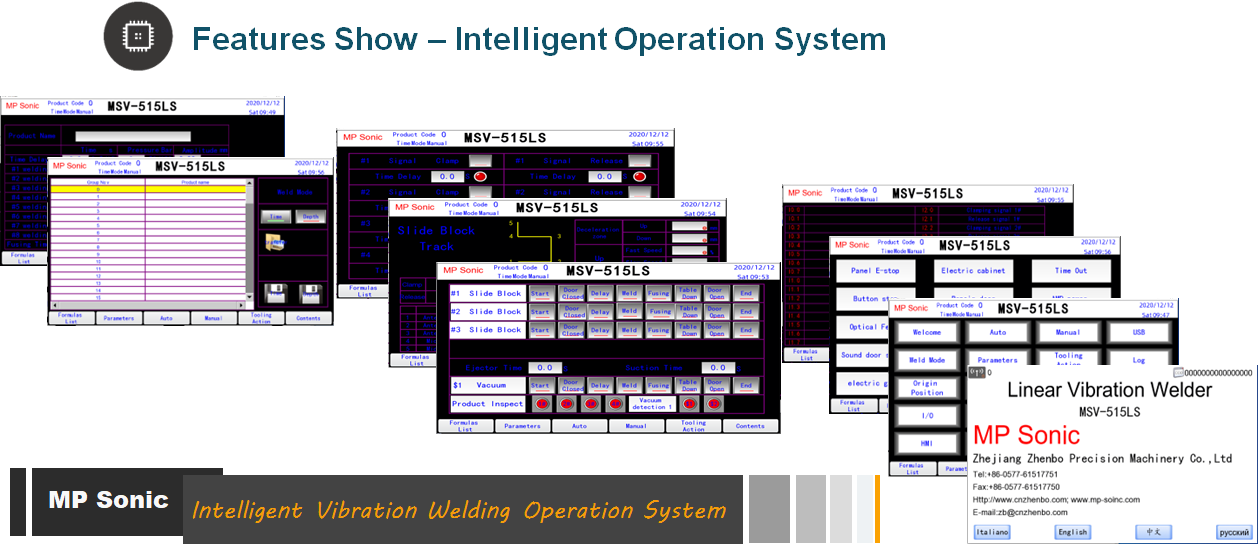

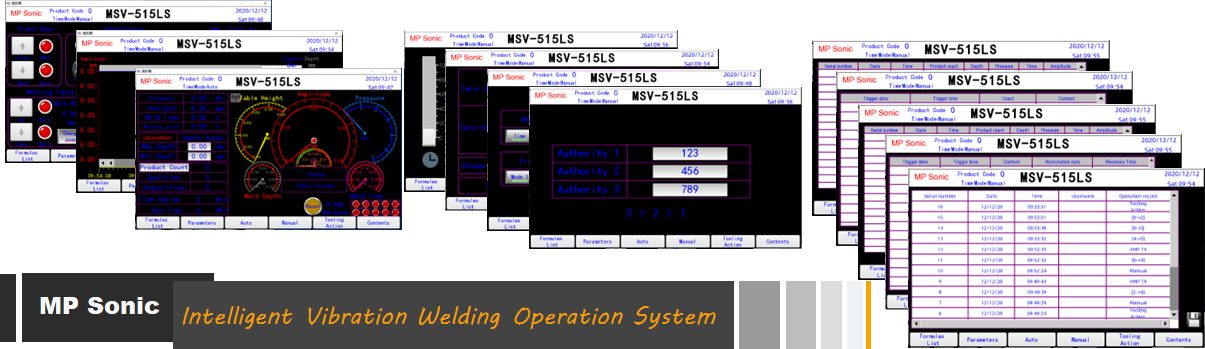

3. Intelligent vibration welding operation system;

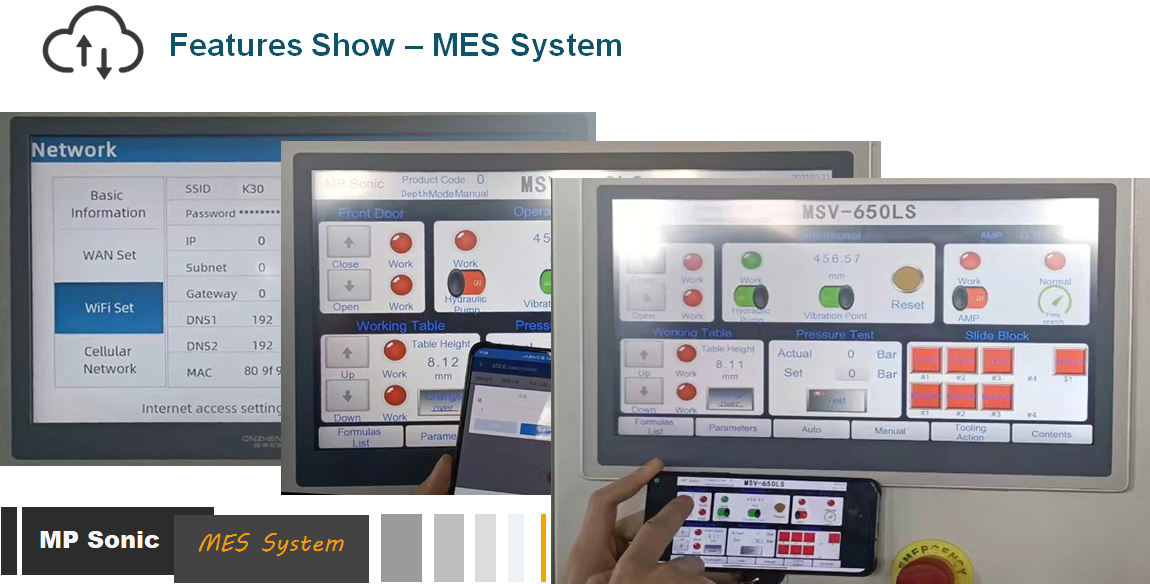

4. MES system for Network & I-cloud remote service.

III. Features Show:

IV. Specification:

Model

MSV-SF730

MSV-SF715

MSV-SF650

MSV-SF615

MSV-SF515

Vibration Head

Weight upper tool

70 Kg

55 Kg

40 Kg

30 Kg

15 Kg

Welding area(approx. for PP)

450 ㎠

280 ㎠

200 ㎠

160 ㎠

50 ㎠

Amplitude(peak to peak)

0.3∼1.2mm

Frequency

210~365Hz

Machine

Machine

Width

2705 * 1286 * 2290

2605 mm

1650 mm

Machine

Depth

1286 mm

960 mm

Machine

Height

2290 mm

1990 mm

Operation Window Width

1500 mm

1400 mm

800 mm

Operation Window Height

745 mm

540 mm

Drive Platen/upper Width

1140 mm

870 mm

360 mm

Drive Platen/upper Depth

520 mm

440 mm

310mm

Lift Table Width

1500 mm

1300 mm

1200 mm

Lift Table Width Depth

600 mm

500 mm

Table stroke/Max.

500 mm

300 mm

Height Clearance for Jig

735 mm

500 mm

Electrical

Main voltage(3P)/In put

380V,AC,3P,50/60Hz

Maximum Power/Out Put

30 Kw

23 Kw

15 Kw

10 Kw

5.5 Kw

Control Voltage

DC 24V