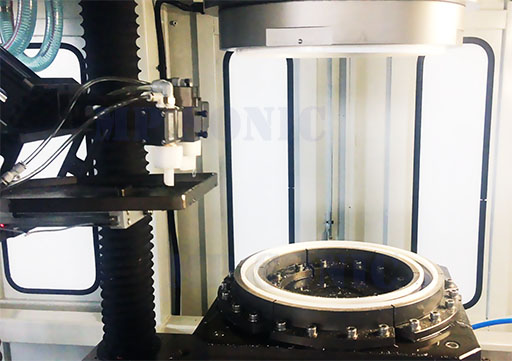

Washer Balancer Spin Welding & Solution Filling Machine

- Category: Products Center

- Phone: Mr Alex Lee (Commercial Director)

- Fax: +86-577-61517750

- Skype: alexlee2696@hotmail.com

- E-mail: info@mp-sonic.com

Description

MPS-T15K-BS is a spin welding machine originally designed by MP Sonic with the advantages of high operation efficiency and reliable welding ability. Machine is designed with two automatic liquid filling system to fill salt water into balancer channels before welding. Machine welding balance with spin friction controlled by servo system, welding depth controlled to ensure welding precision and welding pass ration,

Machine can be applied to weld balance in diameter max to 530mm, operation cycle time minimum 25S depends on solution filling volume and operation action speed.

I. Benefit:

- Finish welding & solution filling automatically by one machine, save investment to equipment and labor;

- High efficiency with short operation cycle time, operation for one balancer minimum to 25S;

- Machine strange construction and corrosion resisting, ensure machine duration reliability;

- Spin welding realize the best alignment of two halves of washer balancer ensuring the measurement precision;

- High welding ability, can be applied to weld parts in diameter max to Φ530mm;

- Precision control in welding and solution filling volume, high qualification ration of operation result.

II. Feature Design:

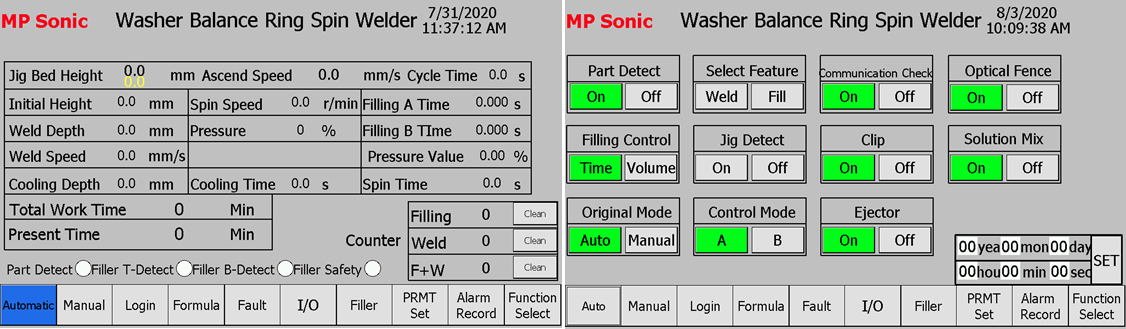

- Welding spindle control with settable parameters including welding speed, welding time, cooling time, welding depth, force pressure fit for different washer balancer specification design;

- Welding programmable process steps control with independent setting to above described parameter fitting for difference injection condition, variation, material to ensure the reliability of spin welding result in qualification;

- Solution filling mode is selectable in time control or certain volume control to fit for different requirement in operation and filling volume accuracy;

- Liquid storage tank is equipped with machine with string system and heating system to ensure stable density to ensuring the control to actual weight of salt water filled into washer balancer;

- PokaYoke system is equipment with machine to avoid operation in part zero presence;

- Ejection system is equipped with machine for easy unloading after welding.

- Machine operation with IOS with multiple function fit for high requirement in production management, quality control, equipment management and easy machine maintenance.

III. Optional Feature:

- SPC traceability system;

- Saltwater mixing & storage system;

- Baking test room system.

IV. Specification:

- Power Source: 380V, 3P, AC, 50/60Hz;

- Air source: 0.6MPa;

- Washer Balancer Diameter: Max.530mm;

- Automatic Filling System: 2sets;

- Machine Measurement: L2730*W1630*H2260

- Machine Weight: about 1800KG.

Read more about washer balancer welding.