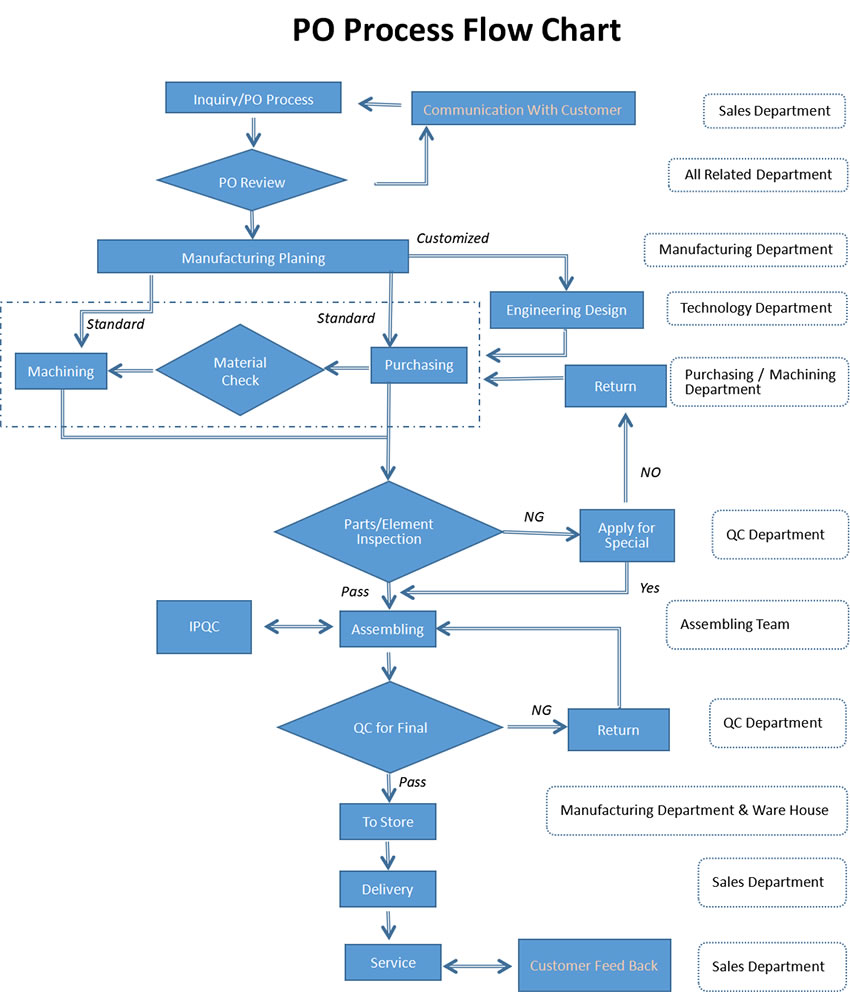

MP Sonic has set serious control program to ensure the quality of equipment supplied to customer, including its Business Flow Charge system and Quality Control System. To ensure the quality of supplied machine, tooling, part and service, MP Sonic pays attention to every detail since the beginning of inquiry from customer to the after-sale-service carried out.

Before manufacturing, MP Sonic keeps carefully communication with customer to ensure fully understand customers’ actual requirement and realize it through MP Sonic designing, if necessary, MP Sonic would like to send professional engineers or experts to visit customers’ factory for face-to-face communication.

Quality is not just concerned to customer's interest, but also critical to MS-SONIC. It concerned to our name presented to the world, will determine our future.

Zhenbo’s quality Policy- Providing high quality products and excellent service to customers.

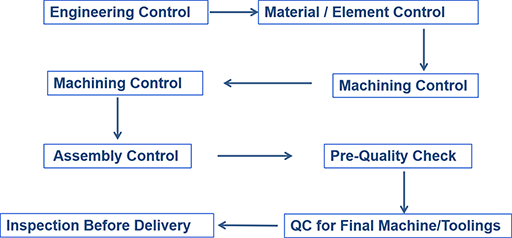

To ensure the qualified equipment and service to our customer, have set a follow system for our quality control.

1. Engineering Control:

A) Review original design data besing various requirement, considering various potential risk ;

B) Review engineering drawing;

2. Material / clement control: ensure the purchased material & elements fitting with technical standard;

3. Machining control: Making mechanical parts basing on engineering drawing standard, and inspected by special technicans with related device/methods;

4. Assembing control: assembld machine/toolings basing on engineering data guide and standard under by IPQC personed conisists of project engineers;

5. Pre-check: assembling technicians trial, adjust machines and do pre-inspection basing on engineering standard;

6. QC: QC person finish final quality inspection basing on engieering standard and technical documents;

7. Inspection before delivery: ensure the equipment condition is good and the content along with packing list before packing.