Closestool is necessary for a family, and intelligent closestool seat cover now is more and more welcomed for its comfortable toilet experience. The assembly closestool cover requests thermoplastic joint to toilet seat because of its safety standard.

I. Why it requests welding to toilet seat?

The heating system inside toilet for warming requests waterproof of assembly of toilet seat.

II. Material: A. ABS; B. PP.

III. Weld Methods: A. Hot Plate Welding; B. Vibration Welding.

IV. Critical requirement: A. Airtightness; B. Beautiful outlook welding result; C. Protection to surface.

V. Challenge of Welding:

A. Toilet seat parts is in big size, big deformation exists in molded parts before welding;

B. None uniformed shrinkage of injection moulding bringing high difficult to reach good welding result in outlook, which requests high precision control in welding;

C. Material especially PP is more challenging than ABS.

VI. Suggested Welding Methods: Vibration Welding.

VII.Advantages of Vibration Welding to Toilet Comparing Hot Plate Welding:

A. Can rectify the deformation of parts before jointing;

B. Stability in qualified welding result;

C. Realize relined welding process control in high precision.

IX.Suggested Welding Equipment:

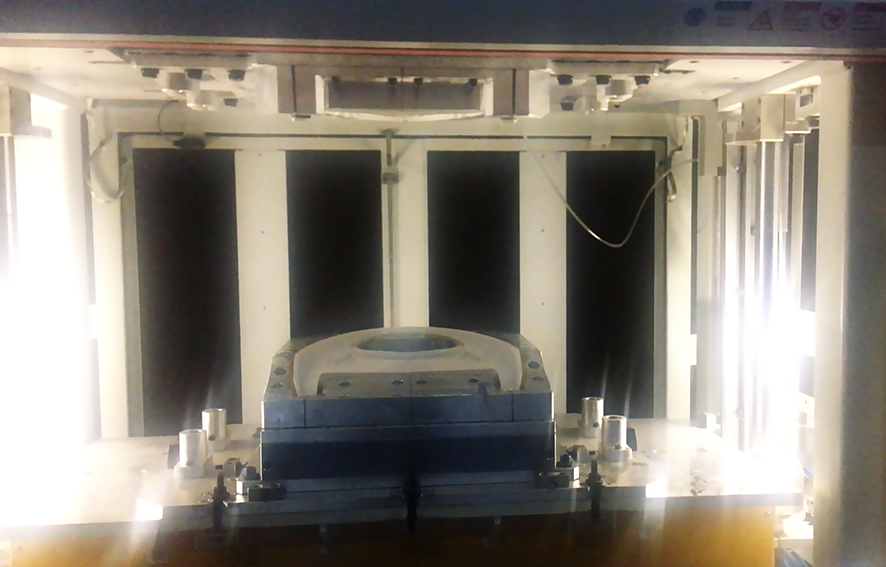

A. Machine: Linear Vibration Welder MSV-650LS (Read Machine Detail);

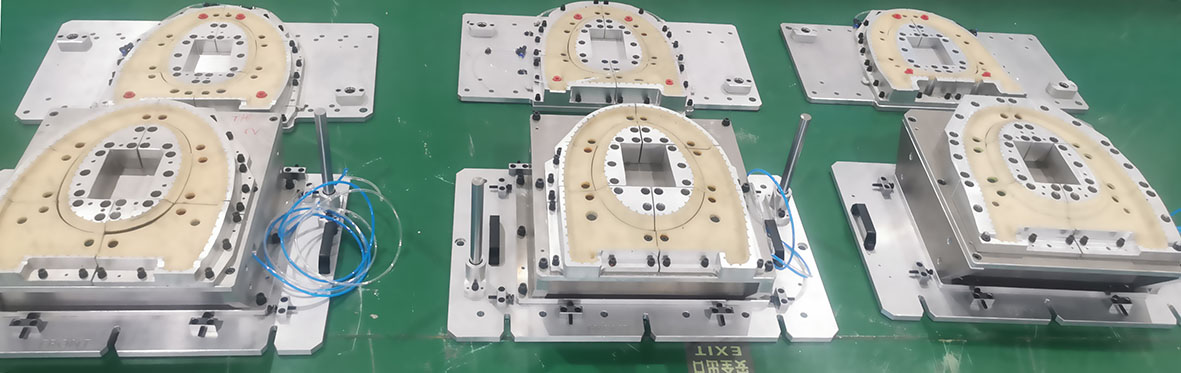

B. Linear Vibration Welding Tooling.

X. Images of Equipment

Video