RO tank, means Reverse Osmosis Storage Tank. Ro tank is applied for storage clean water in water treatment system and propels clean

RO tank, means Reverse Osmosis Storage Tank. Ro tank is applied for storage clean water in water treatment system and propels clean

water out with the air pressure in RO tank.To meeting the food standard, RO tank material normally is PP, and as the working principle of RO tank, it requests high air pressure storage in side of tank, the pressure normally is up to 4MPa or more, thus the design of RO tank is complex, as well the welding of RO tank is very challenging.

I. General information of normally applied RO tank:

1. Specification: mostly applied is 2.0, 3.2, 4.4 gallons;

2. Material: PP;

3. Inner Pressure Storage: 2.8~4.0 MPa;

4. Welding Width: 8~12mm.

II. Requirement of Welding to RO tank;

II. Requirement of Welding to RO tank;1. Air-tight;

2. High welding strength;

3. No pollution cased to RO tank inside;

4. High qualification rate.

III. Challenging in Welding:

Because of high pressure inside of RO tank, the wall thickness and the width of welding is big. To meet the technical requirement it, it request high welding ability and high welding clamp force.

IV. The Ideal Welding Equipment for RO tank;

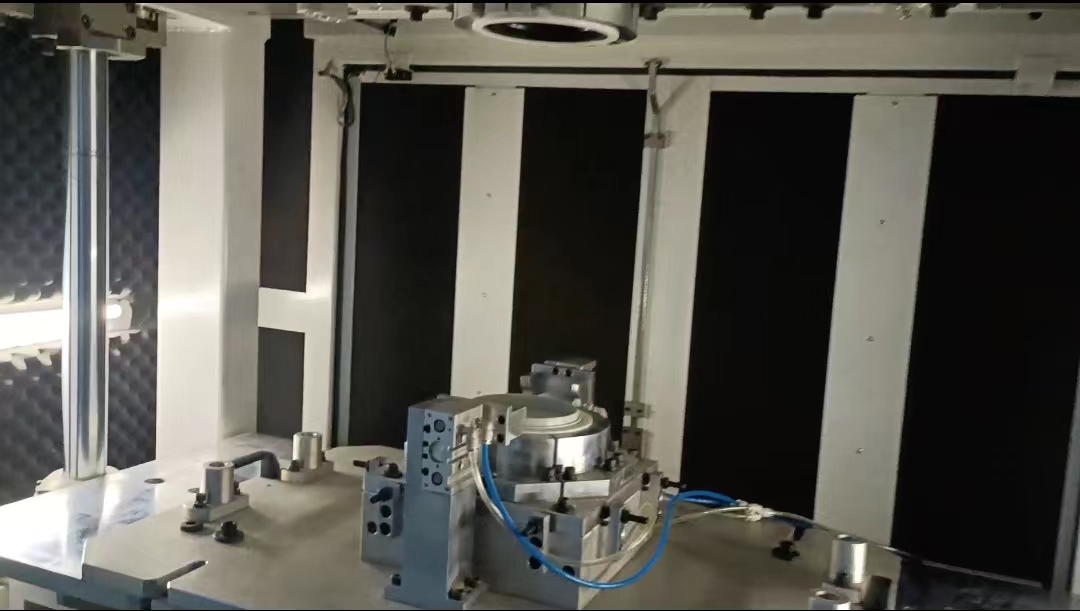

A. Linear vibration welder: MSV-650LS (40KG for 2.0~3.2G; MSV-715LS (55KG) for 3.2~4.4G; MSV-730LS (70KG) for over than 4.4G (Read Machine Specification)

B. Welding Tooling: Vibration welding tooling Made of High-Speed Steel, designed basing on RO tank specification and machine applied.

Note: It requests send 3D data for our welding analysis before final conform the machine specification and joint design.

V. Why Choose Vibration Welding but Not Hot Plate Welding?

Because the high pressure inside RO tank during its working, it requests high pressure force for welding which is not easy realized by normal pneumatic hot plate welding or servo motor hot plate welding, and the speed of hydraulic system action can not ensure the molten state after hot plate melting before re-closing of two fixture, as well, the rubber bag inside RO tank requests being clamped by O-Type right, but cannot be molten and joining, on one hand it requests keep material from heating by high temperature, on the other hand it requests high precision control in depth to ensure both the welding strength and rubber bag clamp strength, which cannot not ensure its the stable control result by hot plate welding because of the melting result by directly heating of hot platen.

VI. Why Choose MP Sonic Vibration Welding Equipment?

1. Higher welding ability and possibility by MP Sonic vibration system with higher frequency than others brands;

2. Strange machine construction design ensure its reliability and duration, ensure products welding stable result;

3. MP Sonic servo hydraulic achieves the best vibration welding result to RO tank;

4. MP Sonic professional technical team provides expert support in your products developement and production.