Hydrogen Storage Tank Infrared Welding Machine

- Category: Products Center

- Phone: Mr Alex Lee (Commercial Director)

- Fax: +86-577-61517750

- Skype: alexlee2696@hotmail.com

- E-mail: info@mp-sonic.com

MSH-IR5090 is the vertical construction designed infrared welding machine from MP Sonic designed to hydrogen storage tank of new energy automotive for tank dimension max to Φ500*H900 (mm).

Machine applies independent IR power supply systems to control infrared heating temperature of upper tooling and lower tooling in different area. Machine applies servo systems to drive welding tooling motion and force welding. Trimming system is applied to trim the injection molded tank halves at joining area in neat condition. During welding, steps process control in precision through independent technical setting at different process steps, including motion speed, motion distance, force pressure.

MSH-IR5090 is applied to weld hydrogen storage tank at the middle of tank height from two tank halves only, for tanks which contents 3 pieces requesting two welding area, please check horizontal type welding machine.

I. Machine Application: welding to plastic storage tank.

II. Main Features:

1. Close-loop IR temperature automatic control system;

2. Full servo control, welding tooling in high speed and high precision, welding process in steps control for challenging welding requirement;

3. Even infrared melting is ensured by REM system, ensuring reliability of tank welding result.

4.Automatic trimming system with waster material collection system is designed to machine to pre-trim tank edge at welding area to ensure welding performance;

5. Machine is designed with IOP system with huge functions in machine operation and management;

6. Network with MES system for high management requirement and remote service.

1. Precision in welding control;

2. Reliability in welding result;

3. Stability in performance;

4. Intelligent in operation and management.

III. Main Technical Parameters

1. Power Source: 380V, 1P, AC, 50/60Hz;

2. Air Source: 0.6~0.8MPa;

3. Power Consumption: about 20KVA;

4. Max welding area: Φ500 (mm);

5. Max tank size: Φ500*H900 (mm);

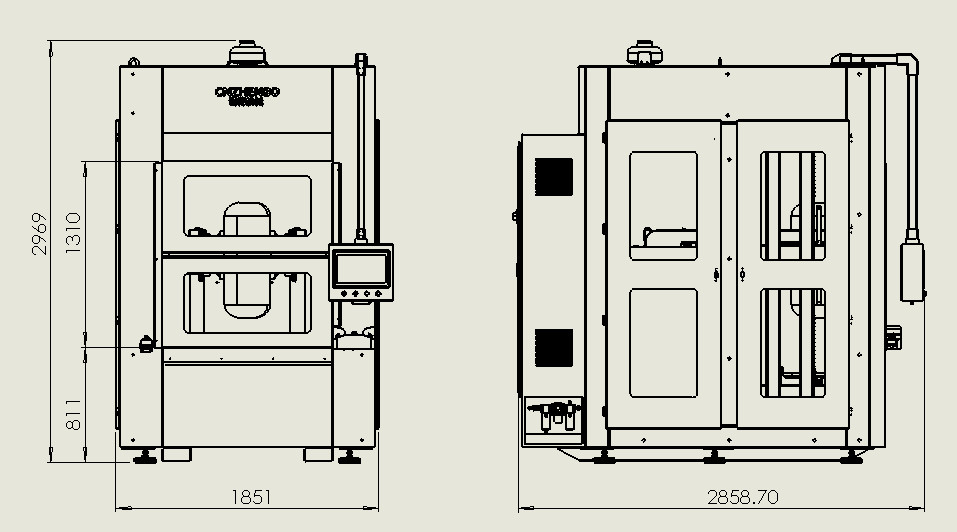

6.Dimension: L1851*D2859*H2969 (mm);

7. Weight: about 6T.

IV. Machine Measurement Layout:

Note: MP Sonic design assembly solution for hydrogen storage tanks according to customized requirement.